Quality Assurance Policy

It is well defined, implemented in true sense & recorded. Quality system practice is given the utmost priority at all levels in the company. Products confirming to agreed customers’ specifications & delivery on time.

Our aim is to do perfect job both individually and collectively - first time and every time. Focusing on Continuous up-gradation of technology, active involvement of all level employees & channel partners to get increased productivity with required

quality.

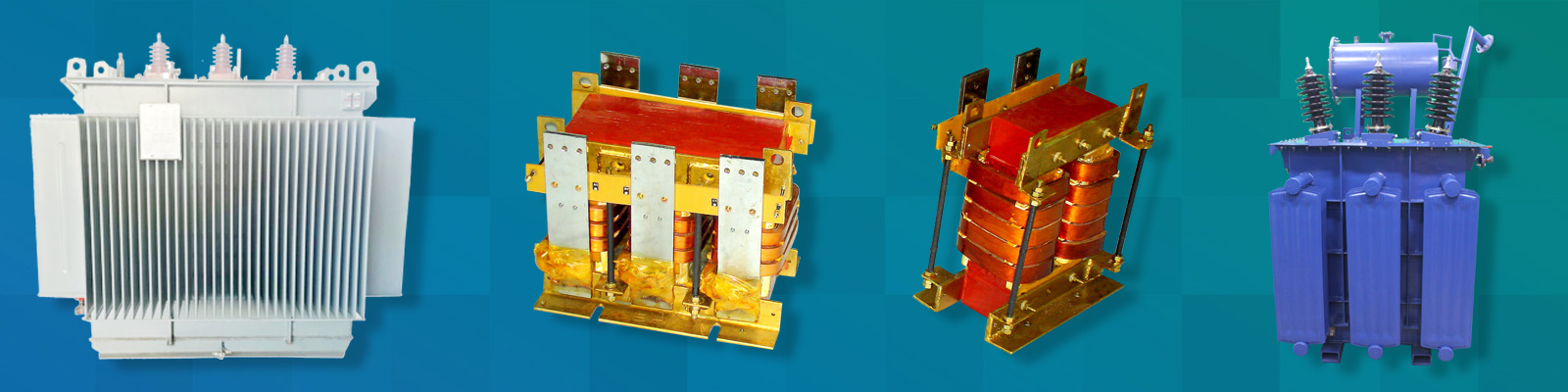

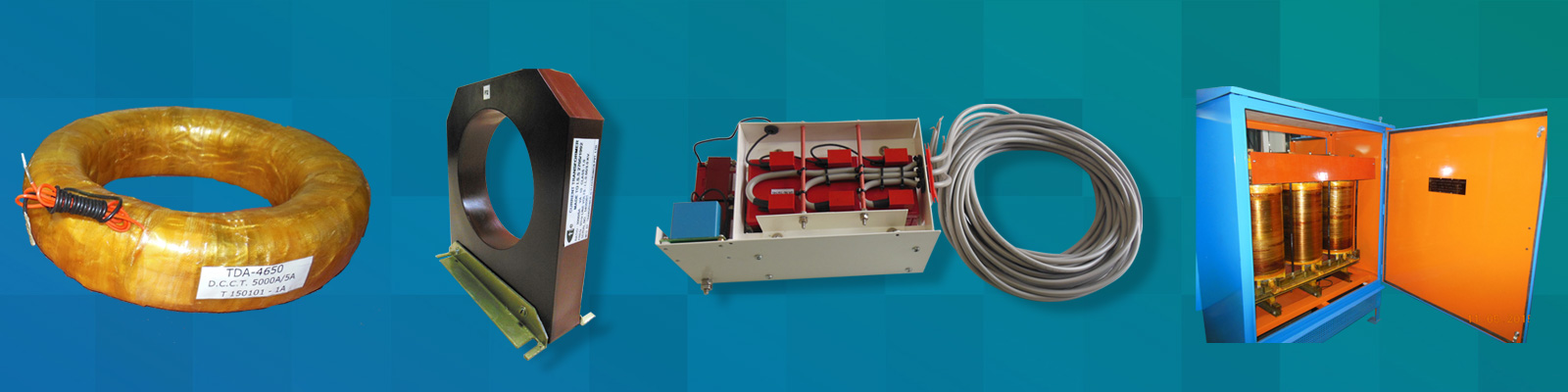

Manufacturing Facility - All essential equipment/machineries are installed to achieve safe & un-compromised quality production. Full-fledged furnace to get stress free cores by annealing process. Vertical & horizontal winding machines for handling heavy weight coil winding. In house designed Core cradles to have smooth core assembly of different size. In house designed insulator

processing equipments. Vacuum chamber for epoxy moulding of CT’s, PT’s & Encapsulated transformers coils. Large Vacuum impregnation plant to have uniform varnishing of coils & firm binding of cores which helps to prevent transformer from moisture absorbing & vibration.

Large capacity air circulation ovens are available to have perfect baking of coils & Transformers.

Argon welding facility to have oxidation free, firm joint between copper to

copper & copper to aluminium.

EOT Cranes & material handling equipments for smooth & safe handling of materials, assemblies & finished products.

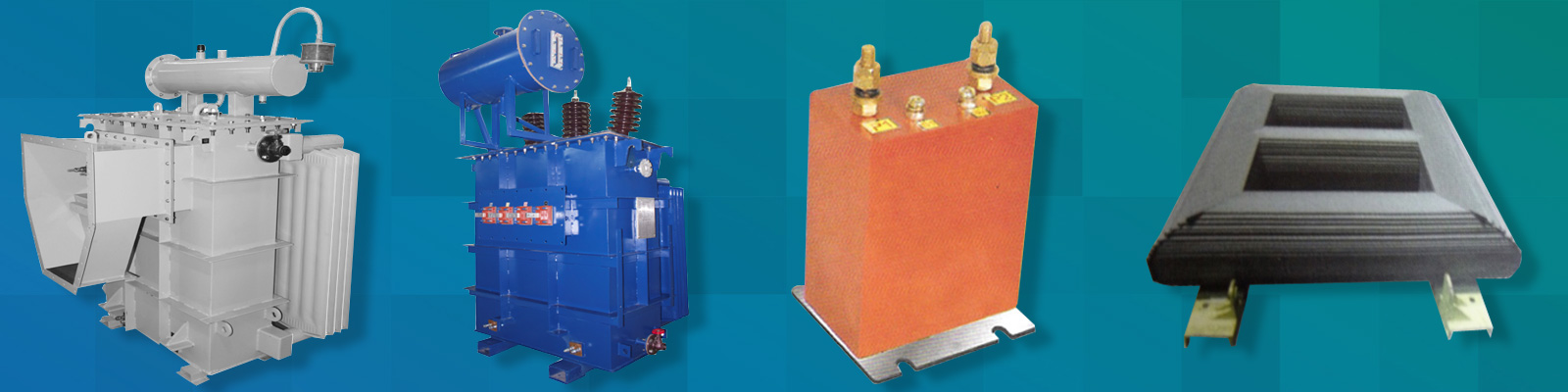

Testing Facilities

A full fledged testing facilities with precision test equipment available for each category products to ensure stage by stage flaw free process starting from raw materials to final products. All routine tests including heat run tests as per IEC 60076, IS 2026, IS3156, IS5553, IS 2705 & IS11171 etc., are carried out in house. Short circuit, impulse tests and other type tests are carried out at ERDA, or at CPRI the most reputed labs in India.

All right reserved by Transpower India Electronics Pvt. Ltd.

Designed by Mirackle Solutions